We are proud distributors of crushing, screening and washing equipment of leading brands worldwide.

We have an extensive range for processing your materials according to your needs and budget.

Get advice from the experts!

Jaw Crushers

Crushers jaws or mandibles work by compression using a tooth fixed and a grinding mobile, the rock remains in the jaws until they are small enough to pass. Of simple and functional design, are of great utility in the primary crushing, and is characterized by a long life of operation, easy maintenance and operation.

We have a wide range and are ideal for the mining, construction aggregates and recycling sectors.

Cone crushers

Cone crushers offer excellent performance in secondary, tertiary and quaternary applications.

They process virtually any material, regardless of its hardness or abrasiveness, and ensure high reduction capacity and efficiency. They are widely used in aggregate production, mining operations and recycling.

All our models are versatile, easy to operate and highly productive.

Horizontal Shaft Impact Crushers (HSI)

For primary and secondary crushing applications of non-abrasive material, horizontal shaft impact crushers (HSI) with their heavy-duty rotor design provide a high level of reduction and generate an outstanding cubical product quality.

HSI primary impacts are generally used in non-abrasive material applications and where fines production is not an issue, e.g. limestone, recycling and cement.

Vertical Shaft Impact Crushers (VSI)

Vertical Impact Crushers have been designed to crush a wide range of rocks, industrial and metallic minerals. They are recommended to obtain a product with small dimensions and excellent cubic properties.

Our extensive line of fully autogenous rock-on-rock VSI machines for the reduction of hard and abrasive rocks and ores. We also offer rock-on-anvil VSI machines for limestone and less aggressive materials.

Need sand? This shredder is the perfect choice for producing a quality product, within specifications, with well-formed cubic particles and the desired modular fineness.

Screens

Screens are used to classify the product into different sizes, shapes or other characteristics depending on the opening of the screen cloth. They work through a shaft mechanism that generates vibration.

There are different types of screens such as horizontal, inclined, multi-incline and high frequency screens, which can be supplied with 1 to 4 beds.

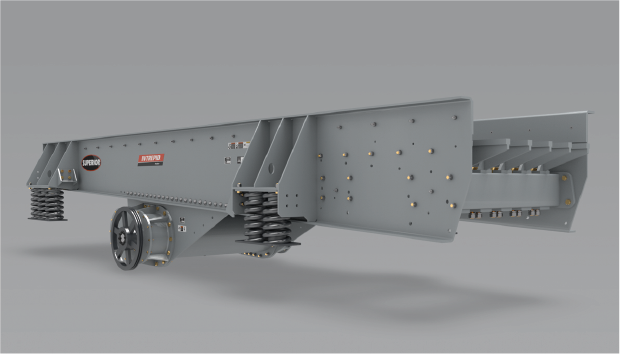

Vibratory Feeders

The function of a vibratory feeder is to control the amount of feed to the plant, separate desirable material from undesirable material and classify it by size prior to primary crushing.

Ideal for applications in mining and production of aggregates for the construction.

Types of feeders:

• Grizzly

• Pan Feeders

• Apron Feeders